Ensuring Manufacturing Resilience: Emerging Trends in Software Manufacturing Solution

In the advancing age of technological progression, the international industrial arena is witnessing a massive paradigm shift steered by the transformative power of intelligent manufacturing. Modern manufacturing resilience is founded on the backbone of ever-advancing software solutions designed to usher in a new era of efficient production paradigms.

These advancements are not just enhancements but absolute overhauls of traditional approaches. The Internet of Things (IoT), a revolutionary integration in this arena, intertwines devices and systems in an interconnected web, improving functional visibility and predictive capabilities. Additionally, the strides taken in automation within the manufacturing sphere are ground-breaking. These automated processes, powered by the advancing manufacturing automation software, replace manual interventions and optimize workflows, ensuring consistency, precision, and scalability.

Let’s dig into the expanse of manufacturing software solutions, which presents many business opportunities. Beyond mere operational enhancements, these software platforms play a crucial role in strategic industrial software development, fostering a culture of proactive planning and efficiency.

Table of Content:

- The Evolution of Manufacturing

- The Rise of Automation in Manufacturing

- Harnessing Artificial Intelligence (AI) in Manufacturing Software

- Journey into Smart Factories

- Internet of Things (IoT): A Game Changer

- Industry 4.0: The Fourth Industrial Revolution

- Driving Resilience with Software Solutions

- The Advantages of Smart Manufacturing

- Navigating Cybersecurity in the Manufacturing Sphere

- Sustainability in Software Manufacturing

- Conclusion

- Frequently Asked Questions (FAQs)

The Evolution of Manufacturing

For ages, manufacturing has been the backbone of economies, evolving with technological advancements and the needs of society. In the past, the manufacturing sector has seen revolutions through mechanization, mass production, and automation. However, the development stands at the precipice of a fourth industrial revolution. This is widely known as “Industry 4.0.”

One of the most important contributors to this revolution is the advancement in automation. Automation began as the primary mechanized system, but now it has been combined with advanced algorithms, predictive analytics, and even machine learning capabilities. For instance, companies like Tesla have embraced advanced automation in their production processes. This has significantly helped optimize their assembly lines and ensure precision.

Another trend reshaping the manufacturing industry is the household name Artificial Intelligence (AI). It improves the operational aspects of manufacturing as well as contributes to forecasting, maintenance, and inventory management.

The Intersection of Resilience and Software Solutions

The concrete foundation of resilience in the manufacturing area is the contribution of software solutions. These solutions are strategic assets as well as operational convenience. For instance, manufacturing software can anticipate potential issues by incorporating predictive analytics and machine learning algorithms. This reduces downtime, minimizes costs, and improves overall efficiency.

The second benefit of smart manufacturing lies in its ability to provide real-time insights. This allows manufacturers to monitor processes, track resource consumption, and analyze whether or not the production lines are running at optimum capacity. Additionally, manufacturing software can monitor the carbon footprint of operations, optimize resource use, and ensure waste reduction.

The Rise of Automation in Manufacturing

No matter what industry you look at, it focuses on automation for its benefits. The same can be said for manufacturing, where industrialization contributes hugely. Automation contributes to production, efficiency, quality, and profitability thanks to technological advancements and software. Let’s look at how the automation software is transforming the manufacturing industry.

The Ever-changing Landscape: From Manual to Automated Processes

Manufacturing has a long history of being a manual process. Humans have been responsible for every processing- from material handling to outcome assembly. This has continued for ages, and even today, there is a manual process in some areas, but it has drawbacks. Some of these include inefficiencies, inconsistencies, and limitations in scalability.

All these are highly minimized in many sectors today. And one of the areas is manufacturing. While automation started as the simple mechanization of tasks, it’s evolved into a complex combination of software solutions, the Internet of Things (IoT), and artificial intelligence (AI). This has given rise to intelligent manufacturing, encapsulating the essence of this transformation. Thanks to these changes, automation can face challenges, devise solutions, and optimize processes, all in real time.

Certified engineers Convenient rates Fast start Profitable conditions Agreement with English and German

EU company

speaking engineers

Remember, AI, coupled with industrial robotics, is refining precision and repeatability, ensuring products are manufactured at a higher rate but with a consistent quality that manual processes could only sometimes guarantee. Furthermore, including IoT technologies means devices, machines, and systems are all strategically interconnected. This allows for real-time analysis, instant feedback, and rapid adaptability.

Case Study: Embracing Automation

Let’s look at the technology company established in multiple domains, including industry, infrastructure, transport, and healthcare- Siemens. Before many companies invested in automation, Siemens heavily invested in its development and integration into their manufacturing processes.

Siemens got an advantage of this by making the optimum use of the manufacturing automation software. Firstly, it decreased production times, leading to faster product turnovers and increased results. Secondly, the quality of their products witnessed minimized errors and more consistency than ever before.

Siemens’s approach to leveraging IoT in manufacturing is a successful case study of real-time data power. Today, Siemens factories are diversely equipped with sensors and devices that continuously relay information. When processed by their manufacturing software, this data provides insights to refine and optimize processes, resulting in a dynamic manufacturing setup.

Harnessing Artificial Intelligence (AI) in Manufacturing Software

Manufacturing software could not have been what it is today without the massive contribution of Artificial Intelligence (AI). Had it not been for AI, the traditional production blueprint would still be in practice. So, what role does Artificial Intelligence (AI) play in the emerging trends of manufacturing software solutions?

Artificial intelligence analyzes significant loads of data in seconds and in real-time. This makes the AI-driven software solution to optimize workflows, reduce waste, and guarantee quality. The concept of smart factories explains this. Smart factories are not just factories equipped with automated machinery.

They are the facilities where every piece of equipment, every process, and every system is interconnected and infused with intelligence. This “intelligence” is AI-driven, facilitating real-time decision-making, predicting machine failures, and enhancing efficiency.

This allows the manufacturers to make strategic solutions by making more informed decisions, reducing downtime, and escalating productivity.

Predictive Analytics and Machine Learning

One of the crucial features of AI in manufacturing is its ability to predict hurdles. Predictive analytics and machine learning facilitate AI-driven software to pinpoint patterns and anomalies in production processes.

By analyzing chronological data and current operational metrics, the algorithms are able to predict when a machine is likely to fail or when a bottleneck is about to occur. Consider a scenario where a production line’s efficiency dwindles due to a specific component’s repeated failure.

In a traditional setup, this might be identified after the fact, leading to unplanned downtime. But, with AI-driven predictive analytics in place, this potential failure can be identified. This allows for proactive maintenance or replacement, which leads to minimal disruption and sustained operational efficiency.

Journey into Smart Factories

A smart factory goes beyond the traditional assembly lines. It’s an advanced environment where machinery, systems, and processes communicate through the Internet of Things (IoT) and other advanced technologies. You can think of it as a factory with a brain, where data-driven insights, thanks to AI and machine learning, drive seamless operations. This gives a much-necessary boost to productivity by minimizing waste and fostering innovation.

It should be noted that the term ‘smart’ isn’t just about automation. The word ‘smart’ signifies a holistic approach where every aspect of manufacturing—procurement, production, or distribution—is effortlessly interconnected, adaptive, and efficient.

What Are the Benefits of Smart Manufacturing?

Integrating smart factories into the current manufacturing scene has been ground-breaking. With AI-driven manufacturing software, predictive maintenance has become the new normal. Machines can self-diagnose issues before escalating, ensuring minimal downtime and consistent output.

That’s not all! Manufacturers now have access to real-time data, which makes the decision-making process more manageable. Manufacturers can also foresee market demands, adjust production rates, and ensure that resources are utilized to their best.

To add to the list of benefits, smart factories also play an imperative role in reducing the environmental footprint, with systems in place to monitor and reduce energy consumption, waste, and emissions. Drawing from real-world examples, many industry giants have already transitioned to smart manufacturing.

Internet of Things (IoT): A Game Changer

The conversation around the Internet of Things (IoT) has steadily gained momentum. It is no longer just a buzzword, and IoT is actively reshaping industries across the spectrum, with manufacturing standing out as a prime beneficiary. But how can manufacturers leverage emerging trends for greater efficiency?

Consider this: a production line where machines don’t just immaculately perform tasks but also ‘talk’ to each other. With the power of IoT, this isn’t science fiction—it’s today’s reality. IoT devices, ranging from sensors on equipment to integrated software solutions, collect and share data. This interconnectedness allows for more streamlined operations, ensuring that machinery can self-adjust based on real-time inputs. This also reduces human intervention, which has room for some errors.

Beyond just flagging issues, the data collected by these IoT devices offers invaluable insights. By analyzing this data, manufacturers can uncover patterns, predict machine wear and tear, and preemptively schedule maintenance. Such proactive measures are pivotal in improving overall efficiency and prolonging machinery life.

For instance, if a raw material batch is detected to have inconsistencies, IoT-enabled sensors can immediately relay this information to the production line. The machinery then adapts, ensuring the end product remains of the highest quality. This precision minimizes waste as well as generates consistent quality results.

Industry 4.0: The Fourth Industrial Revolution

Images of steam engines and factory assembly lines might emerge when we think about industrial revolutions. But today, we’re witnessing the rise of the Fourth Industrial Revolution, also known as Industry 4.0. Unlike past industrial revolutions, Industry 4.0 was created by the fusion of the digital world with the physical, reshaping manufacturing industries’ operations.

Industry 4.0 has several components that drive its influence on manufacturing. First, the Internet of Things (IoT) has been crucial. The interconnected web of devices, communicating and sharing data in real-time, has given birth to smarter, more efficient factories. Big Data and Analytics have taken center stage with the vast influx of data. This offers invaluable insights that drive informed decision-making and enhance operational efficiencies.

Artificial Intelligence (AI) and Machine Learning, two other pillars of Industry 4.0, are taking manufacturing to a new evolution. Systems learn and adapt using AI based on data patterns, optimizing operations. Machine learning algorithms can precisely predict potential issues, allowing businesses to address problems before they escalate.

That’s not all! Robotics and Automation have also seen a ground-breaking transformation. Modern robots in the manufacturing sphere are no longer limited to monotonous tasks. They are dynamic, capable of collaborating with humans, and can execute various operations precisely and efficiently.

How are Manufacturers Adapting to Industry 4.0?

Across the globe, manufacturers are making use of the potential that this revolution holds. The adaptation process, however, requires strategic moves. A fundamental approach has been investment in training. As technology evolves, so do the skills needed to harness its potential.

Progressive manufacturers emphasize training programs, preparing their workforce for the nuances of Industry 4.0. Another strategic shift has been the emphasis on partnerships. Recognizing that the transition to Industry 4.0 is challenging, many manufacturers collaborate with tech providers and industry experts. These partnerships provide them with access to the latest tools, technologies, and insights, ensuring a smoother transition.

In addition to this, pilot programs have also gained popularity. Manufacturers run pilot projects before fully integrating Industry 4.0 principles to understand the practical challenges and benefits. Such projects are learning opportunities, helping manufacturers refine their more extensive implementation strategies.

Lastly, with increased digital integration comes the imperative need for robust cybersecurity. Manufacturers are prioritizing cybersecurity to secure their operations while maintaining their data integrity.

Driving Resilience with Software Solutions

As industries grapple with global challenges, from supply chain disruptions to evolving consumer demands, software solutions emerge as the linchpin for resilience. These digital tools empower manufacturers to respond to uncertainties with agility, ensuring stability and success in volatile environments.

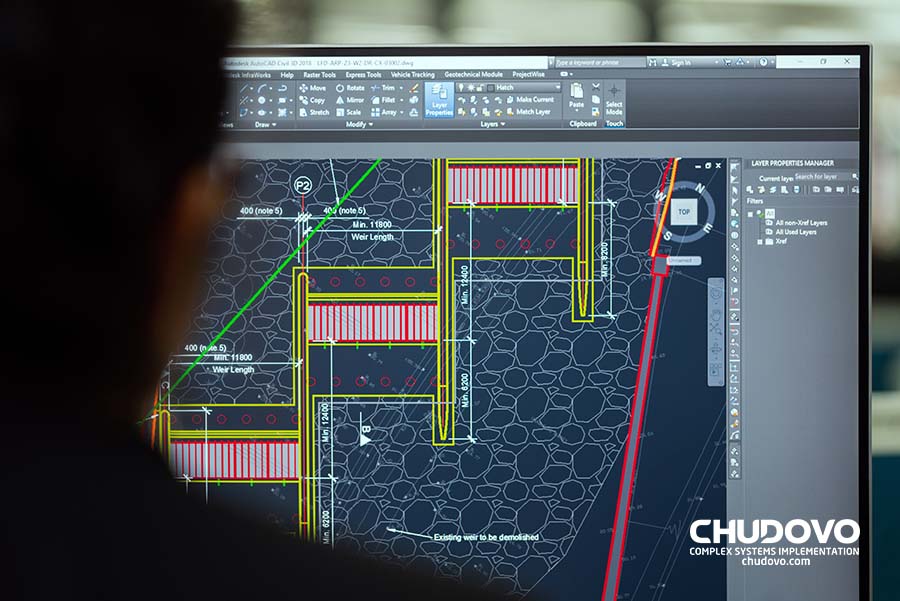

In modern manufacturing, essential software innovations have transitioned from basic functions like tracking and reporting to more diverse and transformative roles. Manufacturing Execution Systems (MES) are at the forefront of this shift, providing real-time monitoring and control over production processes, ensuring that resources are optimally utilized, and manufacturing workflows run efficiently.

Integrating machine learning and AI into Predictive Analytics Tools becomes crucial as we dive deeper into the digital era. These tools proactively identify and address issues, significantly minimizing downtime and bolstering product quality. At the same time, the inclusion of Industrial IoT platforms in manufacturing has catalyzed a paradigm shift, enabling seamless inter-device communication and giving birth to smart factories.

Yet another groundbreaking innovation is the Digital Twin Technology, which allows manufacturers to fashion a digital counterpart of a physical process or product. Supply Chain Management Software has been introduced to enhance operational visibility, granting a comprehensive overview of the supply chain. These software solutions fine-tune inventory management, oversee shipments, and utilize predictive analytics to forecast demand, guaranteeing prompt product deliveries and minimizing wastage.

The Advantages of Smart Manufacturing

By now, you must be wondering- what makes smart manufacturing so appealing? The answer lies in three significant benefits: cost savings, time efficiency, and unparalleled quality.

Cost Savings: One of the primary goals of any industry is to keep costs at a minimum while maximizing output. By incorporating emerging trends in manufacturing, such as automation and IoT, manufacturers can significantly reduce operational costs. Automated machinery, driven by advanced manufacturing software, can operate continuously without frequent breaks, ensuring consistent production levels.

Moreover, inherent to manufacturing software planning, predictive analytics and machine learning algorithms can preemptively identify potential breakdowns, reducing maintenance costs and fewer production halts.

Time Efficiency: The adage “time is money” rings especially true in manufacturing. Traditional methods often involve lengthy processes and manual interventions. However, with AI and industrial robotics integration into the production line, tasks are completed at an unprecedented speed. This rapid pace, combined with real-time monitoring and optimization from IoT technologies, ensures that products reach the market faster.

Unparalleled Quality: Smart manufacturing isn’t just about speed and cost; it’s equally about the quality of the end product. Automation in manufacturing, steered by precise software solutions, ensures that each product adheres to stringent quality standards. Consistency is the hallmark of automated processes, and with the right software in place, manufacturers can guarantee that each item rolling off the assembly line matches the desired specifications and quality benchmarks.

Navigating Cybersecurity in the Manufacturing Sphere

The modern manufacturing arena has come as a boon to many aspects of the manufacturing process. However, it has its share of some risks, particularly cybersecurity. One major obstacle in software adoption is striking the right balance. While employing technologies such as the Internet of Things (IoT) and AI-driven software solutions offers unparalleled efficiency, they simultaneously expose manufacturers to a wide array of potential cyber threats. The stakes are high; sophisticated cyber-attacks, data breaches, and unauthorized access can pose significant dangers.

For example, a malware attack targeting a single IoT device can have a cascading effect, potentially disrupting manufacturing and resulting in costly downtimes. To address these challenges, a holistic approach to cybersecurity is imperative. Regular software updates are crucial, ensuring that all integrated systems are fortified with the latest security patches. Additionally, segmenting the manufacturing network can act as a safeguard, ensuring that breaches in one segment don’t jeopardize the entire operation.

In addition to all this, the human element is equally critical. Regular employee training sessions can equip them with the knowledge to identify and guard against potential threats. On top of this, measures such as multi-factor authentication can further safeguard against unauthorized access.

The true power of advanced threat detection lies in predictive analytics and machine learning algorithms. These tools can anticipate and neutralize threats, often before they manifest into tangible problems. Lastly, fostering a collaborative environment where manufacturing and IT teams work closely ensures that security measures are comprehensive and robust.

Sustainability in Software Manufacturing

The manufacturing landscape of today is one that increasingly aligns with sustainable imperatives. This shift results from an evolving corporate conscience and a reflection of a global consumer base that ardently seeks products birthed from sustainable practices.

In heeding this clarion call, the software solutions powering today’s manufacturing processes are intricately woven with features that uphold eco-friendliness. This encompasses everything from energy conservation and waste reduction to the ethical sourcing of raw materials, all underscoring the pivotal goal of satiating present needs without imperiling the prospects of future generations.

Advanced algorithms are now redefining the landscape with smart resource allocation. By accurately predicting demand and tailoring production to these forecasts, these algorithms ensure that factories harness resources like water, energy, and raw materials with unparalleled efficiency, curtailing wastage.

The proliferation of the Internet of Things (IoT) has ushered in an era where devices equipped with real-time monitoring capabilities become the custodians of energy efficiency. These devices precisely gauge energy consumption, empowering manufacturers to finetune processes and eliminate redundant energy drains.

Predictive analytics has been transformative, especially in preempting machinery maintenance needs. Instead of adopting a reactive stance to equipment malfunctions, these tools proactively signal potential breakdowns. The result? A dramatic dip in operational halts, ensuring that energy and materials are used judiciously.

Digital twin technology has also carved its niche, allowing manufacturers to craft digital replicas of processes or products. These virtual avatars facilitate extensive testing and simulations, negating the need for exhaustive physical trials and the associated resource expenditure.

Transparency has also found its champion in contemporary software solutions, especially in supply chain management. With an eagle-eyed view of the entire supply chain, manufacturers can validate the sustainable origins of their raw materials and guarantee that each product’s odyssey, from inception to completion, is sustainable.

Conclusion

The future of manufacturing hinges on integrating advanced software solutions. We’re building a more efficient and resilient industry by embracing innovations like automation, IoT, and sustainable practices. This evolution promises improved operations and a step towards a greener future. In short, as technology and manufacturing converge, the horizon looks promising and sustainable.

FAQs

What key trends are shaping the resilience of modern manufacturing?

The primary trends shaping the resilience of modern manufacturing include integrating advanced software solutions, automation, smart manufacturing practices, and sustainable, eco-friendly methods. With the addition of IoT and Industrial software development, manufacturing processes are becoming more efficient and adaptable to changing market dynamics.

How do emerging software solutions play a role in enhancing manufacturing productivity?

Emerging software solutions, especially those rooted in automation, predictive analytics, and the Internet of Things (IoT), play a pivotal role. They streamline processes, anticipate issues before they arise, and allow for real-time monitoring and adaptation, reducing downtime and optimizing resource usage. Additionally, smart factories and digital twin technologies offer simulation capabilities, enabling manufacturers to test and refine processes virtually, thus enhancing productivity.

Why is sustainability becoming a focus in manufacturing software trends?

As global awareness about environmental challenges grows, there’s a push for industries, including manufacturing, to adopt eco-friendly practices. Manufacturing software trends now focus on minimizing waste, optimizing resource usage, and reducing carbon footprints. Furthermore, sustainable practices are seen as an environmental imperative and a means to achieve long-term operational efficiency and cost savings.