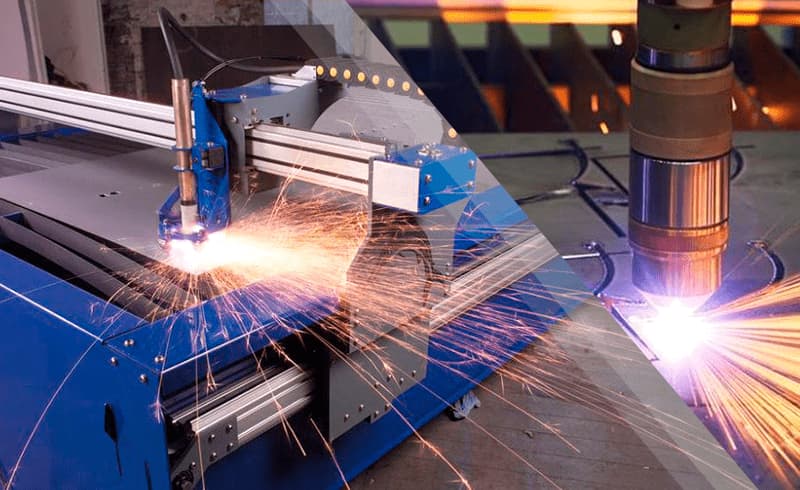

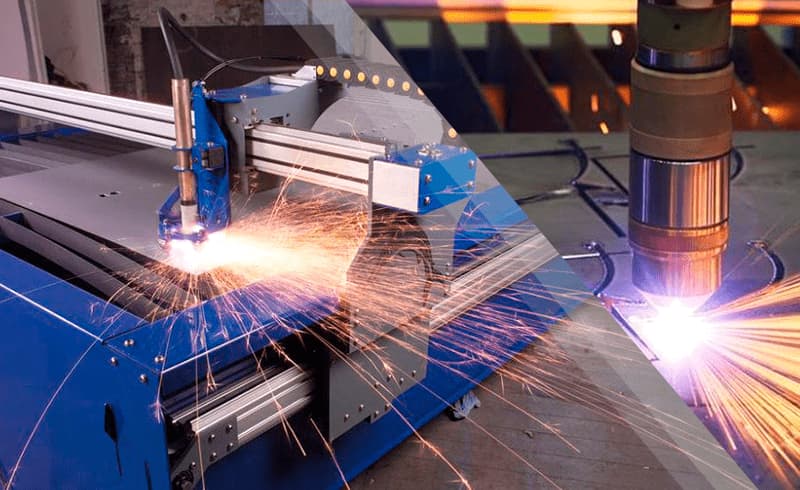

Advanced manufacturing software enables the operation and configuration of bevel-cutting machines. In the first place, the solution is aimed at simplifying, improving, and automating the production and angled cutting of steel/metal. The software with adjustable modes and parameters helps to increase production efficiency and reduce the number of defective products.

Metal Cutting Software

- The customer hired an experienced WPF developer with several years of experience in the industry and thus extended his software engineering team in a short term

- Hired WPF software developer improved the customer's metal cutting software for the bevel cutting machines, extended its functionality and executed all the works according to the set deadlines

- Custom software development services were provided with the high level of quality

Advanced manufacturing software enables the operation and configuration of bevel-cutting machines. In the first place, the solution is aimed at simplifying, improving, and automating the production and angled cutting of steel/metal. The software with adjustable modes and parameters helps to increase production efficiency and reduce the number of defective products.

Business Challenge

Customer’s company is a big concern that focuses not only on machines & equipment production but also offers a big range of solutions for metal working industry. With intelligent solutions and cutting technologies company has remained one of the leaders in metal metalworking industry over the years. In addition, the customer’s solutions meet all global industry standards. To stay up-to-date and industry compliant the customer constantly analyzes the needs and challenges of the metal working branch.

At this moment the company has its in-house development team as well as dedicated software engineering teams distributed across different locations. While contacting our team, the client had an aim to hire a senior WPF developer with proven experience in custom .NET desktop development. Generally, the main requirements to the developer were the following: several years of experience in software development, professional knowledge of .NET/WPF stack, and excellent soft and hard skills. Furthermore, WPF developer should be able to show professionalism in practice. In other words, to apply his previous experience for further professional development of software for controlling the operation of the machine for sheet metal cutting.

Solution

Hired .NET desktop developer started his work on the project of the global supplier of cutting-edge technology in mechanical engineering. The main area of responsibility: constant software support and implementation of customer requests. In general, an intelligent digital cutting machine controls the operation of a machine for bevel cutting in a 2D plane. The system can support the N-number of different machines. Software controls cutting operations such as cylindrical holes, straight cuts, exact bevel angles, and parts with absolute dimensional accuracy. The bevel-cutting tool is flexible to adjustments of all technology parameters according to the needs of production. For example, the operator can customize the sizes, offsets, and frequency of cuts.

The software has several modes depending on the machine used as machines can have different technology parameters, capabilities, and performance. The metal cutting software for bevels is easy to use as it has a user-friendly interface. The software also includes a history module. Thus the system saves the history of all operations, parameter adjustments, responsible operators, the number of connected machines, etc. The sheet-cutting software is aimed at both small and large enterprises. Software is developed for production process automation, shortening production times and reducing the risks of manufacturing defects occurrence.

Business Impact

In general, WPF development for the mechanical engineering industry requires a high level of concentration and dedication from the desktop developer. The software engineer performed the tasks, had good response times, and always tried to propose unique solutions to resolve all the challenges. The client was happy with the performance of the developer and with the quality of the executed works.

Currently, the product continues to be popular in the manufacturing market. As a result, the customer attracts new factories to use the optimized angled metal cutting software. Software for manufacturing processes remains industry standards compliant, helps to boost the efficiency of the production lines as well as to produce a quality product without defects.

Advanced manufacturing solutions

Digitalization and the application of technologies in production boost the efficiency and productivity of the manufacturing business. Maximize the revenue, save costs, and benefit from the efficiency of configured manufacturing workflows. Advanced manufacturing software solutions, featured in your business, will enable simple process management. Besides, manufacturing software can cover many more areas starting from stock availability tracking, production planning, and resource allocation up to full automation of production lines and furthermore.

Contact our professional team to communicate about the main needs of your manufacturing business and possible cooperation in optimizing internal workflows. Let’s check the potential of the manufacturing software for your production.

- The customer hired an experienced WPF developer with several years of experience in the industry and thus extended his software engineering team in a short term

- Hired WPF software developer improved the customer's metal cutting software for the bevel cutting machines, extended its functionality and executed all the works according to the set deadlines

- Custom software development services were provided with the high level of quality