How Software Modernization is Driving Digital Transformation in the Manufacturing Industry

Using software modernization in manufacturing is an effective way of enhancing production in this fast-paced technology world. This is powered by the latest software tools that improve the functionality, security, and performance of products utilizing the said new manufacturing innovations.

Table of Content

What is manufacturing software?

These are software that helps an organization improve its process of production by boosting and increasing the effectiveness and precision of production. This type of modern software will enable the focus to be on crucial aspects of production by seamlessly eliminating wasteful procedures.

It helps manufacturers organize and handle procedures effectively and in an economically feasible way, reducing activities that are not needed. It aims at simplifying and optimizing recurring manufacturing processes, which includes managing stock production planning and organizing resources, and gives an extensive basis for handling the main functions of business operations like quality control and assurance – helping a business maintain high-quality product that meets the satisfaction of their users, handling expenses and planning – helps in tracking costs of production and examines its process in order to reduce shortages without jeopardizing product quality, capacity planning – assessing the capacity of quantity for manufacture required to meet anticipated market demands. This assessment includes available infrastructure such as workforce, equipment, and technologies.

This type of software is able to track business operations while automating production processes for guaranteed development and efficient delivery. It leverages contemporary advances in technologies to solve production problems. These are technological developments designed to enhance the quality and speed of production at different stages of distribution or supply networks.

For highly discerning activity, this modernized software is used to aid the productivity of workers, enhance business operations, and get very efficient and quick solutions to any flaw in the production processes. Modern software solutions streamline manufacturing operations in today’s digital world.

What is software modernization?

The primary goal of software modernization is to enhance the system to be faster more secure, and intuitive to use. This means revamping the source code and changing to a new platform, enhancing visual appeal and experience. In a couple of instances, an entire overhaul is needed.

It involves restructuring the current software from an outdated framework to the latest technology. This modernization involves infusing new technologies into a conventional software design and product to enhance performance, precision, and efficiency. A modification is done intensively to the former software by upgrading it so that it can function using the latest technology. Software modernization deals with the replacement, recycling, and updating of applications or services on the platform where it functions.

To modernize an older version of software involves maintaining part of the old code base, structure, language, and how it is used. However, when developing new software, the building process starts from scratch.

Software modernization attempts to make an old version better, reliable, and suitable for use. Computer techniques in recent years, help in the upgrade of the original code base of a platform to a new platform where it can utilize the latest technologies to function with high performance.

Leveraging software modernization in the manufacturing industry is a game changer because software used in production become highly performant, scalable and efficient in solving procedure. This will strengthen the productivity of a business, help gain more revenue and overall improve customer satisfaction.

Features of manufacturing software

- Manufacturing management and preparation.

This is the organizing and setting up of the steps involved in production. Obligations such as the arrangement of workloads and development of employee schedules help in enhancing production operations, making sure products are completed at due time, and meeting market demands and standards. It improves productivity and minimizes time and supplies used in manufacturing.

This feature fuses the planning of production and scheduling. There exist salient differences in the two processes. With production planning, Bill of Material (BOM) data is accumulated with the goal of properly distributing resources, while production scheduling establishes the stock-keeping units (SKU), a process that enables sellers to monitor available stocks for sale and products are complete. This feature gives more details about controlling product manufacture, as well as adequate control and management.

- Bill of material.

This provides comprehensive descriptions of goods and supplies necessary for the manufacturing of products an organization sells. Bills of material can achieve the appropriate steps for finalizing production across all company production facilities because the details needed to build a product are now available in all departments responsible for the manufacturing process.

Using a bill of materials, businesses can prepare for purchasing resources, manage and organize stocks, and eliminate delays in manufacturing and waste. A more precise bill of material can identify the basis of an item problem and help speed up the repair of the defective parts and components.

- HR management.

This feature in manufacturing software can handle important details about workers in an organization concerning the time they spent working, payment and deduction from paycheck. It helps in the confirmation of wage information and can optimize taxation proceedings.

It helps in maintaining staff members, decreases recruitment requirements by enhancing employee management, guarantees compliance with rules and regulations, simplifies operations, boosts interactions, enables information-driven choices, increases the general output and effectiveness.

- Inventory management.

Stock level and availability can be properly managed because you can ascertain the number of materials needed for the production of specific goods and identify the completed products to be sold and distributed. A modernized software with this feature will be able to give detailed information about the quantity of stock available for either production or finished good for distribution.

You can get accurate updates on your stocks on hand and indicate if your materials for production are not enough – in this case, you can easily restock and avoid scarcity. This will help to choose the correct substance and quantity necessary for the manufacturing of a complete product.

- Quality management.

This provides an extensive understanding of quality assurance processes, and enables organizations to promptly identify and address errors and other manufacturing challenges, thus safeguarding clients’ satisfaction, and commitment and stops problems from escalating.

Creating products with outstanding quality should be the primary objective when considering features for manufacturing software. Your consumers are pleased when you give them quality items, urging individuals to come for more and refer to your products. An enterprise quality management software will ensure a high standard of what you produce and corrective and preventive action to make the product stand out in the market.

- Warehouse management system.

This technology enables a proper arrangement of the warehouse space, handles the goods in stock, and enhances the operation of the warehouse. Selecting will enable you to choose your desired item, supervise how stocks are kept in the warehouse for easy identification of products, and barcoding, which involves scanning a code to help recognize a product.

It helps an enterprise handle and oversee activities in the warehouse, spanning the moment the product reaches distribution and completion facilities until it is taken out of the premises. In the supply chain management system, this software is used to modernize its solution because it gives visible information about a company’s supplies inside the warehouse and the ones shipped.

- Supply chain management.

In the manufacturing sector, implementing this software solution offers awareness and central supervision throughout the preparation, development, production, supplies, and shipment aspects essential for the goods produced by an organization. Procedures with suppliers can be managed seamlessly, processes of purchase are enhanced, and track shipment to ensure resources are accessible on schedule.

Collaboration and communication between suppliers, manufacturers, and consumers are optimized. There are self-service platforms available that help users to easily handle estimates and orders for goods. Consumers can customize the type of item they want online – by providing detailed information about their desired item.

Benefits of manufacturing software

The use of digital technology throughout manufacturing processes enhances the way goods are produced, delivered, and tracked, giving numerous benefit that increases productivity, reliability and performance procedures.

The concept of the Internet of Things and artificial intelligence has prompted the transformation in the manufacturing industry using modernized software. These are some digital innovations used to enhance production by overhauling old procedures. Information can be gathered from various devices through digital transformation.

Hardware and software management, as well as operating expenses and the costs of hiring a labor force, are cut down, helping a business expand in order to reach a wider audience. In the manufacturing industry these benefits are characterized as software modernization. By harnessing digital innovations and information gathered by companies, they can strengthen business processes and effectiveness in developing unique solutions.

- Enhanced effectiveness.

Digitizing business procedures will enable producers to simplify boring operations, lower inaccuracies, and boost efficiency. The duration used in production, evaluation, and shipping is shortened using digital technologies like automation, which speeds up these processes.

Method of operation and interaction across organization divisions can be smoothly achieved using these modernized technologies. In the manufacturing industry, modernizing software means facilitating the fabrication processes to seamlessly meet the needs of consumers. With the small size of staff, companies will easily finish up production as the automation of different processes of operations, like handling stock availability, production time management, and resource utility, can be carried out using this tool.

- Edge in competitiveness.

Digital transformation gives businesses a better opportunity to stay relevant and compete in an ever-evolving marketplace. Contemporary technologies, if not utilized by organizations in production, could find themselves out of the race in no time. An extremely competitive industry requires that production companies constantly investigate approaches that will help their businesses surpass their rivals through the enhancement of their operations and products.

- Improved customer satisfaction.

Businesses will get a better understanding of customer buying habits and choices, enabling the production of better-suited products and services with the help of modernized software transforming digital spaces in the manufacturing industry. This will increase consumer contentment and retention. When production companies focus on meeting what their customers want and offer excellent service to their clients, this makes such organizations stand out. Using this software solution helps organizations to improve manufacturing standards further, the timeline for shipment, and personalized items according to client’s tastes, which leads to high consumer satisfaction.

Certified engineers

Convenient rates

Fast start

Profitable conditions

Agreement with

EU company

English and German

speaking engineers

Example of software modernization in the manufacturing industry

1. Enterprise resource planning software.

Within an enterprise, it is possible to connect multiple business procedures and departments together using a comprehensive ERP system. This software modernization involves modifying your existing system to a better one, accompanied by an upgrade from on-premise to cloud-based ERP. There are many good reasons for modifying your ERP:

- eliminating inefficiency in current procedures

- effectively satisfying business demands

- reliability purpose and improving support for the development of the business.

Pros of ERP:

- Optimization of productivity during operation

- Enhances accessibility to essential information

- Suitable for inventory management and monitoring

Cons of ERP:

- It is expensive to set up

- It is majorly used by large organization

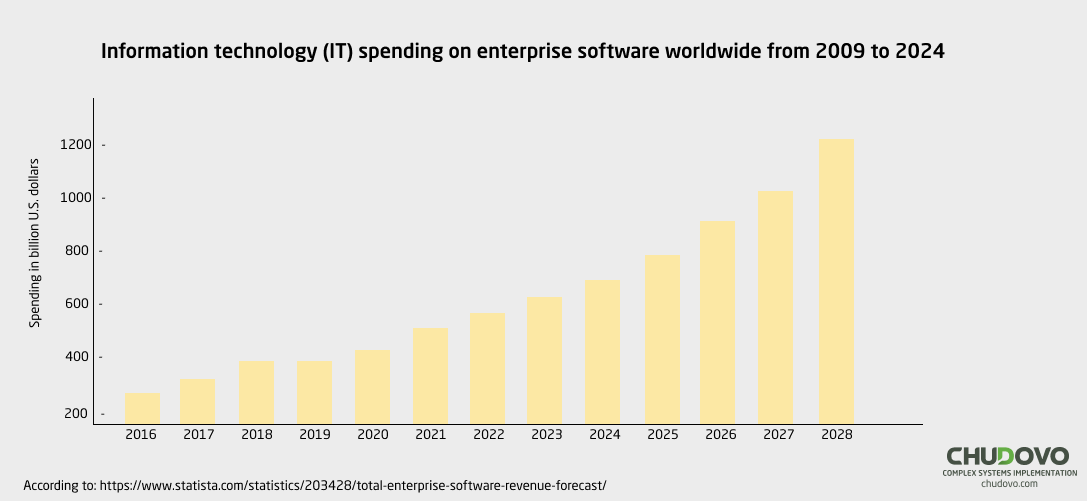

The manufacturing industry has grown in the past few years. According to Statista, This sector invested about $913 billion on software for business globally in 2023, showing a 12.4% increase in comparison with the previous year. With the market revenue enormously doubled in the last decade.

2. Computerized maintenance management system.

It centralizes information to simplify the handling of procedures. Businesses implement this software to upgrade production processes through the modification of outdated systems. With the execution of this system, employees can effortlessly detect and obtain the needed instruments and materials for routine tasks.

Pros of computerized maintenance management system

- Helps organizations to make a tangible use of their material

- It helps enterprises to lower expenses and boosts their work efficiency

Cons of computerized maintenance management system

- Implementing this system into other platforms might be difficult as it does not conform easily with every operating system

- A cloud-based computerized maintenance management system will be an issue if the enterprise decides to customize it.

3. Environment, health, and safety software for manufacturing.

Manufacturing businesses use this software to maintain records and assess health and safety acts while regulating precautionary techniques. With this modernized software system, it becomes easy for organizations to oversee and provide information on ecological performance, guidelines, and operational threats. Firms can maintain the original operating system of their platform while they use this software to upgrade the functionality and effectiveness in order to strengthen welfare and safety arrangements in their production procedures. It examines danger and establishes the importance of risk prevention while controlling operation management.

Pros of environment, health, and safety manufacturing software

- Organizations can make decisions based on reality that will improve the safety of workers.

- It helps businesses to identify which production procedure and equipment uses a larger amount of energy

- Organizations can easily evaluate how well resources are utilized in comparison to production.

Cons of environment, health, and safety manufacturing software

- Reliance on this tool gives little chance for communication between teams

- With the innovation of new technologies come different kinds of hazards that are not constant. Hence, it is hard to prevent

4. Computer-aided manufacturing Software.

This is used to upgrade an existing system such that manufacturers fabricate things using their computers because now they no longer need to manage machines in the traditional mode of operation. With this software, they can mass-produce accurate designs and patterns.

Pros of computer-aided manufacturing software

- It is used for reiterated activities to offer lightning-fast and accurate manufacturing processes.

- It does not have to be regulated by a person because the process runs autonomously

Con of computer-aided manufacturing software

- It requires crew members who are very highly experienced to operate the system

- It takes time for employees to learn and get comfortable using the software

5. Computer-aided design software

In product design and development, this software plays an important role because it allows users to put together and modify the electronic representation of their goods, recreate, and obtain thorough technical diagrams. The development procedures are fastened for the product design steps, and risks of error are reduced. Design quality and efficiency are improved using this tool. Engineers can use CAD to investigate production procedures and also generate improved layouts.

Pros of computer-aided design software

- Enterprises use this software to bring their creative concepts alive

- Using this software can help identify possible manufacturing challenges

- It gives a high level of accuracy because, inside the software, there are tools that can validate designs

Cons of computer-aided design software

- Organizations need to put up extra costs so that they can train their employees on how to use the software

- It needs regular or constant updates of the operating system

- It takes time to be able to get familiar with its use in creating designs for production

FAQ

What is the role of software in manufacturing?

It helps manufacturers organize and handle procedures. It helps an organization improve its process of production by boosting and increasing the effectiveness and precision of production. It aims at simplifying and optimizing recurring manufacturing processes, which includes managing stock production planning and organizing resources, and gives an extensive basis for handling the main functions of business operations.

How does IT help in manufacturing?

The use of digital technology throughout manufacturing processes enhances the way goods are produced, delivered, and tracked, giving numerous benefit that increases productivity, reliability and performance procedures.

What are the five types of software used in manufacturing?

There are numerous types of software used in manufacturing that seamlessly boost productivity and efficiency in production. Here are some of the popular types

- Enterprise resource planning software

- Computer-aided design.

- Computerized maintenance management system.

- Material requirement planning software.

- Manufacturing execution software.

What is the process of software modernization?

This is the process of modifying, improving, and reorganizing existing software with the primary objective of making it efficient, safe, and simple to use. It involves restructuring the current software from an outdated framework to the latest technology. This modernization involves infusing new technologies into a conventional software design and product to enhance performance, precision, and efficiency.

Contact the Chudovo engineering team to modernize your software so as to transform your manufacturing business.